What are the classification methods of copper pipes?

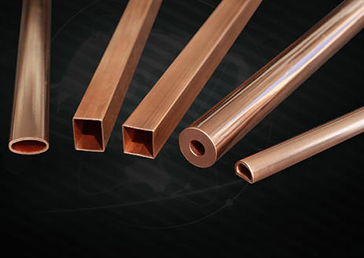

Copper tube, with good heat dissipation and strong practicability, is widely used. There are many types and specifications of copper pipes. Now let's talk about the classification specifications of copper pipes?

The classification specifications of copper pipes are as follows:

1: According to different welding methods, welded copper pipe can be divided into arc copper pipe, high-frequency or low-frequency resistance copper pipe, gas copper pipe, furnace copper pipe, Bondi pipe, etc.

Electric welded copper pipe: used in oil drilling and production and machinery manufacturing.

Copper tube raw material specification: furnace copper tube: it can be used as water gas tube, etc., and large-diameter straight seam copper tube is used for high-pressure oil and gas transportation, etc; Spiral copper pipe is used for oil and gas transportation, pipe pile, pier, etc.

2: According to the weld shape, it can be divided into straight seam copper pipe and spiral copper pipe

(1) Straight seam copper pipe: simple production process, high production efficiency, low cost and rapid development.

(2) Spiral copper pipe: the strength is generally higher than that of straight seam copper pipe. It can produce copper pipe with larger diameter with narrower blank. The raw material specification of copper pipe can also produce copper pipe with different diameter with blank of the same width. However, compared with the straight seam pipe with the same length, the weld length is added by 30 ~ 100, and the production speed is low. Therefore, straight seam welding is mostly used for small-diameter copper pipes, and spiral welding is mostly used for large-diameter copper pipes.

Article from:http://www.hsfuyi.com

-

03-04

What are the characteristics of aluminum tubes?

Value of aluminum tubeGuangdong aluminum tube factory provides you with explanations. Aluminum tubes appear in a wide range of aerospace and commercial industrial applications, including entertainment products and machine parts. Although the content of aluminum is only one-third that of stee

-

02-04

What are the processing methods of copper pipe?

There are three methods for processing copper pipes:1. The kneading process of copper tube clarifies that the definition of kneading process is that the copper embryo tube is kneaded and formed by the copper tube kneading machine, and then the density distribution and wall thickness of the c

-

01-20

What are the classification methods of copper pipes?

Copper tube, with good heat dissipation and strong practicability, is widely used. There are many types and specifications of copper pipes. Now let's talk about the classification specifications of copper pipes?The classification specifications of copper pipes are as follows:1: Acco

-

12-15

How to electrolytic purify copper tubes?

The first is to use the thick steel plate with high copper content in the thick copper pipe as the anode. In addition to making the copper sheet, it can be used as the cathode, and sulfuric acid and copper sulfate solution can be mixed together. For electric transmission, the copper tube will di