What are the processing methods of copper pipe?

There are three methods for processing copper pipes:

1. The kneading process of copper tube clarifies that the definition of kneading process is that the copper embryo tube is kneaded and formed by the copper tube kneading machine, and then the density distribution and wall thickness of the copper tube are more uniform, and then the stronger compressive performance can be achieved.

2. Copper tube continuous casting and rolling process: the definition of continuous casting and rolling process is continuous casting and continuous rolling, and then pour the liquid copper burned at high temperature into the continuous caster to roll out the copper billet (called continuous casting billet), and then directly heat preservation in the soaking furnace for a specific time without cooling, and then directly into the hot continuous rolling unit for rolling. Continuous casting and rolling process can skillfully combine casting and rolling processes. Compared with the traditional process of casting copper billet first and then heating in heating furnace and then rolling, it has the advantages of simplifying process, reducing labor force, increasing metal yield, saving materials, enhancing continuous casting billet quality and producing energy-saving and environment-friendly copper products, which directly realizes mechanization Advantages of programming and automation.

3. The process of copper pipe upward drawing method illustrates that the original feature of upward drawing continuous casting copper pipe is "no oxygen", that is, the oxygen content is less than 10ppm. Electrolytic copper is melted into copper liquid at high temperature and transformed. In the whole process after hardening, charcoal reduction, flake graphite masking and oxygen isolation are adopted. Oxygen in molten copper liquid is a new type of copper oxide and cuprous oxide. Charcoal can deoxidize itself under the action of high temperature to make its oxygen content less than 10ppm. Due to the oxygen isolation effect of CO shielding gas and flake graphite in the process of chemical reaction, graphite will no longer be oxidized in the crystallization process, and then reach the role of updraft process.

Article from:http://www.hsfuyi.com

-

03-04

What are the characteristics of aluminum tubes?

Value of aluminum tubeGuangdong aluminum tube factory provides you with explanations. Aluminum tubes appear in a wide range of aerospace and commercial industrial applications, including entertainment products and machine parts. Although the content of aluminum is only one-third that of stee

-

02-04

What are the processing methods of copper pipe?

There are three methods for processing copper pipes:1. The kneading process of copper tube clarifies that the definition of kneading process is that the copper embryo tube is kneaded and formed by the copper tube kneading machine, and then the density distribution and wall thickness of the c

-

01-20

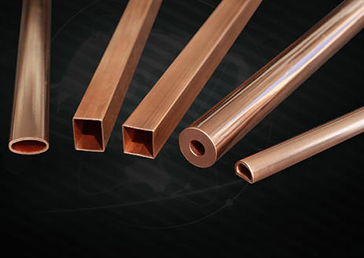

What are the classification methods of copper pipes?

Copper tube, with good heat dissipation and strong practicability, is widely used. There are many types and specifications of copper pipes. Now let's talk about the classification specifications of copper pipes?The classification specifications of copper pipes are as follows:1: Acco

-

12-15

How to electrolytic purify copper tubes?

The first is to use the thick steel plate with high copper content in the thick copper pipe as the anode. In addition to making the copper sheet, it can be used as the cathode, and sulfuric acid and copper sulfate solution can be mixed together. For electric transmission, the copper tube will di