What are the characteristics of aluminum tubes?

Value of aluminum tube

Guangdong aluminum tube factory provides you with explanations. Aluminum tubes appear in a wide range of aerospace and commercial industrial applications, including entertainment products and machine parts. Although the content of aluminum is only one-third that of steel, manufacturers are highly praised for their resistance and applicability. Because of this combination of strength and flexibility, many applications benefit from the use of aluminum tubes.

Characteristics of aluminum tubes

Due to the light weight, the unit weight provided by aluminum pipe is larger than that of steel pipe. Many products benefit from the use of lighter pipe materials, especially those requiring some degree of mobility, such as wheelchairs and field furniture. Aluminum tube will not lose its luster. Compared with other metals, it is easier to accept paint and other decoration, so as to enhance its beauty.

Aluminum has very good thermal conductivity, making aluminum tubes an ideal choice for temperature controlled applications, including refrigerators, solar energy and air conditioning systems. In addition, the application of hydraulic system, fuel pipeline, structure and frame benefits from the light weight and durability of aluminum pipe.

There are several different alloys of aluminum. Various combinations of aluminum with magnesium and silicon form a strong alloy. In particular, the manufacturer uses square tube aluminum alloy 6061 for many medium and high strength applications because of its higher weldability and excellent corrosion resistance. 6061 aluminum square tube is also simple anodized, and its characteristics make it very suitable for heat treatment. It is also a cheaper aluminum alloy tube.

Article from:http://www.hsfuyi.com

-

03-04

What are the characteristics of aluminum tubes?

Value of aluminum tubeGuangdong aluminum tube factory provides you with explanations. Aluminum tubes appear in a wide range of aerospace and commercial industrial applications, including entertainment products and machine parts. Although the content of aluminum is only one-third that of stee

-

02-04

What are the processing methods of copper pipe?

There are three methods for processing copper pipes:1. The kneading process of copper tube clarifies that the definition of kneading process is that the copper embryo tube is kneaded and formed by the copper tube kneading machine, and then the density distribution and wall thickness of the c

-

01-20

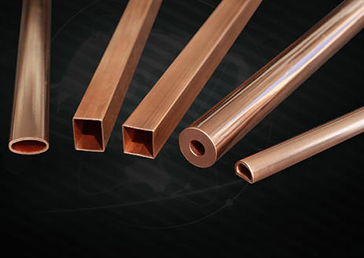

What are the classification methods of copper pipes?

Copper tube, with good heat dissipation and strong practicability, is widely used. There are many types and specifications of copper pipes. Now let's talk about the classification specifications of copper pipes?The classification specifications of copper pipes are as follows:1: Acco

-

12-15

How to electrolytic purify copper tubes?

The first is to use the thick steel plate with high copper content in the thick copper pipe as the anode. In addition to making the copper sheet, it can be used as the cathode, and sulfuric acid and copper sulfate solution can be mixed together. For electric transmission, the copper tube will di